Once Upon a Time This Valve Worked Well

Our process had to be shut down again. It seems that the original valve is no longer up to the task. Should I continue to simply repair the valve or should I look for another solution? Up until now, it was far easier to repair the valve and/or replace it in kind … but my process efficiencies are going down and I need to find a solution. Where do I start?

Changing Conditions

I pull out the valve data sheet and take a look at the original conditions. Wow! I can see immediately that things have changed –

- The plant has aged nearly 20 years;

- We replaced the pump on that line 5 years ago;

- We have modified the piping in the area of the valve;

- We changed the fluid chemistry;

- Instead of operating continuously, the plant is now cycling

Every time conditions change, we need to review the impact upon the control system.

Aging Systems

As a system ages, it does not get any cleaner. Whether it is due to pipe scale or there is other sediment in the system, a valve that worked in a clean system may not work as well in the older system. We have periodically been pulling the valve with cage style trim in order to drill open the passages. We have also noticed that the valve trim is wearing out more quickly. The valve simply requires more maintenance.

New Pump

Installing a new pump can change how the system operates. A new pump generally means that we have a new pump curve to work with. The new pump curve means that the flows and pressures have changed from the original specification.

Modified Piping

We added a new branch line. A closer look reveals (I use my 20D2 rule of thumb) that the new line may have lowered the flow rate through the control valve. Is it possible that the control valve is no longer properly sized? The trim in an oversized control valve erodes more quickly than the trim in a properly sized valve. Alternately, if the valve is undersized, I may be seeing high velocity erosion which also negatively affects trim life.

Changing Chemistry

Although we have always maintained our chemistry within recommended boundaries, we can see that our targets have changed over the years. Newer technology allows us to more closely hit the mark. Is it possible that this has tipped the balance and we are now seeing erosion-corrosion in the valve since the originally specified materials are no longer noble enough?

Cycling vs. Base Loading

When we changed from a base loading operation to a cycling operation, we started to strain our control valves. Now they operate more frequently and often work in the low end of the range. By changing the operation, I now need to have a valve that is suitable for severe service when previously I could use a standard valve.

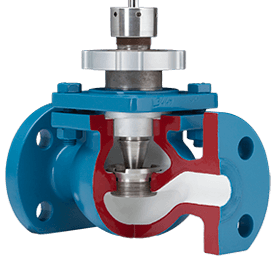

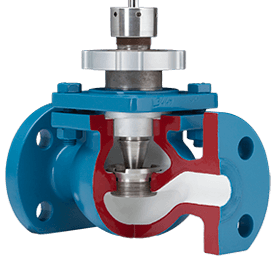

The DFT HI-100™ control valve can be a good choice when conditions change. It deals well with dirty fluid, can be sized properly for the new conditions, is not subject to erosion corrosion and is designed to perform well in the most severe services.

Comments are closed