Control Valve Product Offerings

HI-100® Control Valves

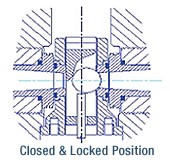

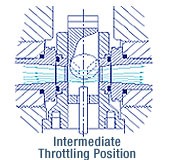

Our HI-100® model is a severe-service control valve featuring an in-line, straight-thru, Venturi-flow design. The seating element, a spherical ball, is contained by a cage that positions it relative to the downstream seat by means of linear stem travel. There are no close clearances between the moving parts (i.e., cage, ball, and seat).

These features enable the valve to operate smoothly and efficiently at high or low temperatures, and/or in fluids carrying suspended particles, such as slurries. The Quick Change Trim feature permits in-line replacement of the internal trim (ball, stem, cage, seats, seat retainer cartridge, and wear bushings).

Plus, the interchangeability of the upstream and downstream seats and wear bushings extends the life of the valve — at no extra cost. This control valve model is composed of carbon, alloy, and stainless steel, as well as high alloys, and functions between temperatures of -425 ºF and 1900 ºF.

The HI-100® meets ANSI standards 150 to 4500. The valve may be completed with a weld, flanged, or custom end prep, and has low operating thrust. HI-100® may be used for manual, pneumatic, electric, and hydraulic actuation, and utilizes top or bottom entry.

View Products

ULTRA-TROL® Control Valves

The ULTRA-TROL® is a flanged abrasive-service control valve designed for lined pipe applications requiring flanged end connections. The internal design features are similar to those of the HI-100® model, and include the in-line through-ported Venturi flow shape and contained spherical ball.

These basic features enable the valve to operate smoothly and efficiently at high or low temperatures, as well as in slurries. The ball, cage, and stem can be easily replaced in-line without removing the valve, and the downstream seat is end loaded for quick replacement. This model can effectively operate between ‑425 ºF and 1000 ºF, and has a flanged end that can be ANSI, DIN, or JIS.

These valves are made of alloy, carbon, and stainless steel, and other high alloys. ULTRA-TROL® valves offer top or bottom entry and have low operating thrust. ULTRA-TROL® may be used for manual, pneumatic, electric, and hydraulic actuation. This model meets ANSI standards 150 to 2500.

View Products

LSV-100® Control Valves

The LSV-100® is an economical control valve for use in top entry, flanged applications. The trim of this valve is replaceable in the field through the bonnet. These valves are constructed of carbon or alloy steel, with stainless steel internals. Other materials of construction are available upon request.

LSV-100® may be used for modulating control or for on/off gas, liquid, and steam applications. This model adheres to Class IV shutoff standards in ANSI class 150 and 300.

The LSV-100® offers top-guided, unbalanced, and single-seat trim. Equal-percentage, linear, and quick-opening trim is available for pressure drops up to 600 psi in non-cavitating environments. Our LSV-100® valves are the most cost-efficient option for standard control applications.

View Products

Our Control Valve Advantage