DFT® Certifications

When you’re considering sourcing from a manufacturer, the certifications the organization holds should be important criteria in the decision-making process. Third-party certificates are an objective way to measure a company’s product quality, operational efficiency, and overall reliability and consistency of service and production.

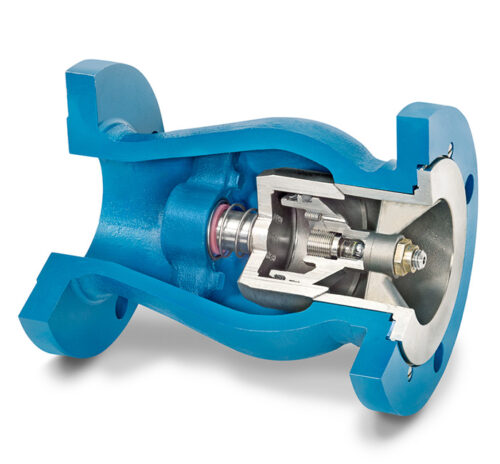

For more than 80 years, DFT®, Inc. has engineered and manufactured in-line check valves and control valves to address valve challenges across diverse industries. Our innovative products are engineered to eliminate water hammer, extend the lifespan of your fluid systems, and make fluid management easier. As part of our commitment to providing high-quality products to our customers, DFT® maintains compliance with multiple industry certification standards.

ISO 9001:2015 Certificate

The International Organization for Standardization, or ISO, has established a set of guidelines to assist manufacturing and industrial organizations in successfully developing and maintaining an effective quality management system. By complying with the standards outlined by ISO 9001, organizations are better positioned to meet internal goals and customer expectations through quality processes and end products. Such standards also promote operational efficiency as well as continual improvement.

ISO reviews and revises its standards periodically to improve and stay current. Standard ISO 9001 was updated in 2015 and then again in 2025. DFT® maintains an ISO 9001:2015 certification, giving our customers the peace of mind that they’re partnering with a company that prioritizes quality in production.

3-A Certificate

3-A Sanitary Standards, Inc. (SSI) specializes in developing standards for hygienic industrial equipment. Manufacturing machinery that handles or produces food, beverages, and pharmaceuticals must meet higher quality standards regarding hygiene to protect consumers and end-users. 3-A certification is given to organizations that meet the current hygienic design and fabrication standards outlined by the organization.

3-A SSI meets approximately once a month to review and revise these standards, as needed. It’s a not-for-profit organization operated by volunteers in three categories: government groups; manufacturers of food, beverages, and pharmaceuticals; and manufacturers of equipment for those three sectors.

MSS Certificate

Manufacturers Standardization Society (MSS) of the Valve and Fittings Industry is another non-profit organization. Members of this technical association and certified organizations work together to set and improve engineering codes and standard practices as they apply to manufacturers of valves and fittings.

MSS designs its standards to benefit not only the industry but also valve and fitting end users. At DFT®, we hold an MSS certification and comply with the industry, domestic, and international standards the organization upholds.

API 6D Certificate

The American Petroleum Institute (API) trade association oversees process and equipment standards for petrochemical and petroleum operations. Its Monogram Program confirms that manufacturing operations in these sectors adhere to API’s established standards. In its Q1 ninth edition, API set forth its requirements for an API-certified quality management system (QMS). Organizations that achieve API certification, like DFT®‘s API 6D certification, have proven their ability to dependably and consistently manufacture API-compliant products.

The API 6D certification covers valves for piping systems and pipelines with natural gas and petroleum industry applications. DFT® also holds an API 6FA certification, which involves fire testing for check valves. For GLC® or Excalibur® check valves that are API 6FA-compliant, reach out to DFT® for class and line sizes.

PED Module H Certificate

Different countries have different standards when it comes to pressure equipment ordinances and manufacturing specifications. DFT® complies with European Union standards as part of our PED Module H certification. To ensure standardization and conformity, pressure equipment in European countries must follow the requirements outlined in the Pressure Equipment Directive 2014/68/EU (PED), which is essentially the uniform pressure equipment law for products sold in the EU.

The directive covers the design, manufacturing, inspection, classification, certification, distribution, installation, usage, and more of the following pressure equipment and accessories:

- Pipelines and pipes

- Regulators

- Relief and safety valves

- Rupture discs

- Pressure vessels and gas cylinders

- Steam boilers and their parts

- Heat exchangers

- Storage tanks

Specifically, PED concerns itself with pressure equipment that has a maximum acceptable pressure PS of over 0,5 bar.

Learn More About DFT®

DFT® is your partner for high-performance check and control valves that consistently meet or exceed quality, safety, hygienic, and industry standards. Our certifications are only one of the ways in which we set ourselves apart from the competition. Learn more about the DFT® difference by visiting our resource library today.