Using DFT Check Valve to Solve High Flow Lockout in Combustion Turbine

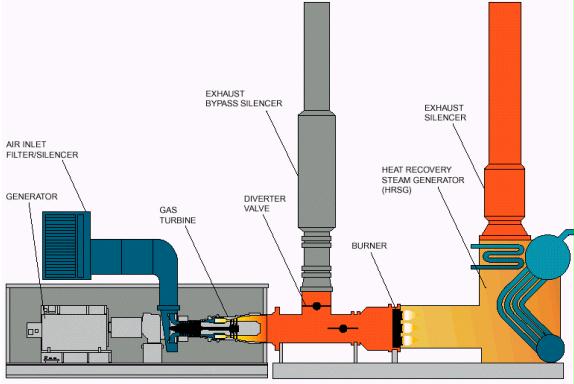

There was a case study done at a power company regarding the installation of the check valve developed by DFT Inc. near the combustion turbine. The GLC Check Valve developed by DFT is connected on Low NOx Dual Fuel Turbines. The combustion turbines can run using diesel fuel or natural gas. When the turbine is fuelled by diesel, water is injected into the diesel in order to increase its power and lower the emission.

A 3” 600# water injection line goes into the turbine. At the turbine, the line is further split into 20 – ¾” lines that are spread out equally around the turbine.

Natural Gas Dilemma

The turbines, as mentioned earlier, can also run using natural gas. However using natural gas requires that the power company must ask for permission from a local gas company in order to fuel the turbines. The problem when using natural gas is that the turbines consume so much that gas companies would need to run their compressor station at max capacity. Failure to do so might affect their downstream customers. When this scenario happens, the turbine combustion is forced to rely on diesel fuels.

High Flow Lockout

Another problem that might occur is the High Flow Lockout. This happens when one of the 20 – ¾” check valves malfunctions, allowing air to go to the isolation valve, which in turn, causes the turbine to fail.

It is hard to pinpoint which of the 20 smaller valves have malfunctioned, requiring the operator to inspect each of the 20 valves individually.

The power company wants to remote start the turbine within 15 minutes of its cold start state. In this case, the only way for it to start quickly, is to utilize diesel fuel.

Solution with DFT Check Valves

The solution to all these problems is the installation of the DFT check valves. The 3” 600# 316SS GLC with soft, seat, sizing and a special spring, was installed on the water injection line near the turbine.

By doing so, the possibility of air backing up in the isolation valve is eliminated. The turbines can now work efficiently, whether using natural gas or diesel fuel.

The installation of the DFT check valves has been in the system for 6 years now, and no failure in the turbine has occurred. Word of the successful solution has spread to other plants resulting in the installation of DFT silent check valves.

Comments are closed