Threaded Check Valves Guide

Threaded check valves are a type of valve that features either internal or external threaded end connections. The term “threaded” refers to the valve end connection, which is the component of the valve that connects with the piping system. This type of valve is typically easy to install and performs very well in applications with various pressures and temperatures. Most often, threaded valves are four inches or under. These components are available with either male or female connections and can be tapered or straight. Tapered threaded valves (NPT ends) will provide a direct seal, while straight threaded valves (NPS ends) will require auxiliary components to provide a seal.

Uses for Threaded Valves

Threaded valves are widely found in applications with stable pressures and temperatures. They can be used in liquid, gas, or steam applications. Industries that commonly utilize threaded valves include:

- Boiler

- Food and beverage

- Power generation

- Pharmaceutical

- Municipal

- Pulp and paper

- Chemical processing

- Water treatment

- Mining

- Test laboratories

- Textiles

- Primary metals

- Gas transmission

- Petroleum production and refining

- Building maintenance

Applications

Threaded valves can be found throughout all industries but are common within the petrochemical industry and can often be found in refineries. They are also a popular choice for boiler and steam applications. In these cases, the environment will typically feature very high temperatures coupled with low pressures.

It is also possible to use threaded valves in applications related to gas or oil production. Unlike steam and petrochemical applications, gas and oil production will feature extremely high pressures, prolonged opening and closing times, and harsh environmental conditions.

Factors to Consider Choosing the Right Threaded Valve

To protect the long-term performance of your piping system, it is important to choose the appropriate threaded valve. There are several factors to consider when making this decision. A significant consideration is the amount of pressure that the valve must withstand. For applications with high pressure, an externally threaded valve is the optimal choice, as it will have a thicker wall than an internally threaded valve.

It is also important to determine whether the valve must provide a direct seal. Applications that require a fluid-tight seal will generally necessitate the use of a tapered valve, as this will provide a seal without the need for any additional components. National Pipe Thread Tapered (NPT) valves are the U.S. standard for applications requiring tapered valves.

Factors to consider when choosing a threaded valve include:

- Temperature

- Pressure

- Tight seal (metal or soft seat)

- Size and weight

- Adherence to industry and plant standards

- Valve permanence

- Ease of installation

- Ease of removal

- Budget

- Inventory simplification

Threaded Check Valves from DFT Valves

Since 1943, we at DFT Inc. have been engineering and manufacturing world-class, in-line check valves for use in a wide array of industries, from petroleum refining to food and beverage.

Our check valves can be installed vertically or horizontally and play an integral role in steam condensate management systems. These systems help maintain high-quality steam, thus preventing the development of many issues within the pipe and valve. In particular, our line of SCV threaded check valves is ideally suited for use in steam condensate applications. These valves feature a range of qualities, including corrosion resistance and longevity, that ensure their high performance in applications of this type.

For over seven decades, our priority has been preventing threaded check valve failures. We are dedicated to providing our customers with threaded valves that are both sized appropriately and suited to the unique needs of each application. To learn more about our offerings, browse our Threaded Valves Catalogue or contact us today.

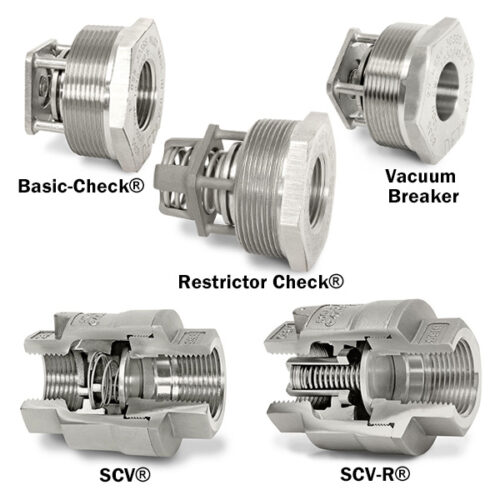

DFT Threaded Check Valves are available in the following types and sizes:

SCV Check Valves – 1/2” to 2” – 750 & 3600 CWP

SCV-R – ½” to 2” –

Basic Check – ¼” to 2 ½”

Restrictor Check – ¼” to 2 ½”

Vacuum breakers – 1”” to 4”

Comments are closed