Category Archive: Check Valves

Webinar Q&A: Solutions to your Check Valve Problems

Check Valve Installation & Piping Design Guidelines

As a follow up from our webinar “Solutions to your check valve problems”, we are sharing, in this post, a few of the questions received from the audience. A variety of questions came in which are answered here by our host Arie Bregman, vice president and general manager of DFT® Inc and a 35-year industry veteran, who is an active member in the U.S. Valve Manufacturers Association (VMA), serving on the group’s education, training, and technical committees.

During the webinar Arie discussed the different factors that go into a well-functioning piping system and ways to prevent water hammer and related issues before they become serious, time-consuming problems. Many times valve problems are not a function of the valve at all, but problems with the piping system design, valve location, poor installation practices or selecting the wrong valve for the application. In the webinar you will hear about check valves within piping design, best practices of installation, choosing the right check valve for the application and even a section on gasket installation best practice.

If you missed this webinar, you can now view it on demand from the DFT website, just click this link.

Below, our talented host answers some common questions regarding check valve applications to help you find the right type and fit.

Q: Can you explain leakage rates for various types of check valves?

A: All of our check valves must meet one of the two most common standards for valves: MSS SP61 and API 598. To test leakage rates, we usually perform the test with either air or water, although water tends to be the more difficult medium. If you’re using your valve in an application that involves gas, you might want to choose the MSS SP61 standard and use gas testing.

Q: Can I use check valves with 50% caustic soda solution? If so, what the minimum temperature?

A: It may be a challenge to use any check valve with such a solution because the caustic soda will likely cause the parts to gradually bind. If you need to use a caustic soda solution, however, we recommend using a special coating such as Xylan on any internal parts that will need to be able to move relative to one another.

Q: How closely does a full bore gate valve approximate a straight pipe? Can this count towards the straight pipe run recommendation?

A: Although a full bore gate valve will have a fairly high flow coefficient, it will still cause flow turbulence. Therefore, you should still place it after the check valve if you plan to use it in place of a straight pipe.

Q: What is the effect on pressure drop for an axial flow check valve?

A: A pressure drop will result in higher flow resistance in an axial flow check valve than it would in a swing style check valve because of the internal pressure within the flow stream. Greater flow resistance, however, isn’t necessarily a problem, particularly if the volumetric flow rate through the collective piping system is also high. You simply need to ensure that the differential pressure created by the axial flow valve enables the valve to completely open at normal flow conditions.

Q: Can you provide a ranking of check valve types from the smallest to the largest pressure drop in the fully open position?

A: Unfortunately, this type of ranking isn’t possible because of the number of variables among the valves. Generally, the highest coefficient by line size would be with a swing style valve, followed by tilting disc, double door (dual plate), and then axial flow valves.

Q: How does cracking pressure relate to pressure drop across the valve?

A : The cracking pressure will be the absolute minimum pressure loss that the valve will experience when in operation. If you need a more precise estimate of the amount of pressure that will be lost, you must do valve-sizing calculations for your specific application.

For more than 70 years, DFT® Inc. has helped customers find and install the right check valves for their unique applications. From world-renowned DFT® Silent Check Valves to the innovative DFT HI-100® Control Valves, we have the products you need and a team of valve experts with decades experience in a range of industries, including power generation, petroleum, construction, chemical processing, steam, water treatment and many more

To learn more about our valves, and how we can assist you, download our eBook, “Check Valve Installation Rules & Guidelines” Or contact us directly.

New Webinar From DFT®: Solutions to Your Check Valve Problems — Important Valve Installation and Piping Design Guidelines

Even one minor mistake in an otherwise well-designed piping system can cause serious, high-maintenance problems — such as water hammer — that can damage pumps and other components. At DFT®, we’ve seen best-case scenarios, and we’ve seen catastrophes, especially involving the installation and maintenance of check valves.

To help understand the many factors that go into a well-functioning piping system and to prevent water hammer and related issues before they become serious, time-consuming problems, we’ve created a comprehensive webinar, “Solutions to Your Check Valve Problems — Important Valve Installation and Piping Design Guidelines.” This presentation will review installation, maintenance, and piping design tips, as well as key guidelines to keep in mind to ensure the most efficient installation and use of check valves.

The upcoming webinar will explain the basics of piping design and the fundamentals of valve sizing, with an emphasis on sizing check valves for specific application conditions, rather than selecting a valve based solely on line size.

Webinar Details

- Date — May 23, 2018

- Time — 2 p.m. EDT (11 a.m. PDT)

- Duration — 1 hour

- Presenter — DFT®

- Speaker —Arie Bregman, vice president and general manager of DFT® Inc. A 35-year industry veteran, Bregman is active in the U.S. Valve Manufacturers Association (VMA), serving on the group’s education, training, and technical committees. He also is a member of the VMA Board of Directors. Bregman holds a Master of Science degree in mechanical engineering from Worcester Polytechnic Institute in Worcester, Mass.

Key Takeaways

- Learn general check valve and piping design rules

- Understand how piping design can impact valve reliability and maintenance costs

- Explore best practices and review check valve installation and valve maintenance guidelines

- Learn how to choose the best check valve for your application

- Hear about common valves myths vs. reality

Register Today

DFT® has solutions for your check valve problems. Register for our webinar today!

Benefits of the WLC® Wafer Style Silent Check Valve

Typically used to restrict fluid flow to a single direction, check valves play an integral role in all types of liquid networks. At DFT® Inc., we’ve been manufacturing top-quality check valves and control valves since 1943. The DFT® Model WLC® Wafer Style Check Valve, a spring-assisted, lightweight model, offers a number of unique advantages over traditional valves.

The dual/center-guided design improves stability, while the disc and seat arrangement ensure a tight shutoff, eliminating the risk of reverse leakage and, therefore, preventing potentially dangerous water hammer. In fact, these valves are ideal for use in systems with a high risk of water hammer. Offering consistent, reliable operation and ensuring low maintenance costs, the WLC® product line can be used for a wide range of pressure/temperature combinations, making these valves ideal for applications involving liquids, gases, and steam.

The dual/center-guided design improves stability, while the disc and seat arrangement ensure a tight shutoff, eliminating the risk of reverse leakage and, therefore, preventing potentially dangerous water hammer. In fact, these valves are ideal for use in systems with a high risk of water hammer. Offering consistent, reliable operation and ensuring low maintenance costs, the WLC® product line can be used for a wide range of pressure/temperature combinations, making these valves ideal for applications involving liquids, gases, and steam.

Wafer Style Check Valves

As mentioned, DFT®’s wafer style check valves are specifically designed to prevent water hammer and reverse flow. Take this recent project as an example:

One of our clients approached us for assistance with an application involving raw water intake; the valves they were using were causing water hammer, and they needed an alternative solution to ensure optimal operational efficiency and reduce the risk of costly maintenance needs and downtime. We replaced the valves with our WLC® models and later assessed the facility during a routine maintenance operation. The water hammer had been completely eliminated. Simply by switching to these check valves, the client was able to fix an issue they had been dealing with for years, significantly reducing the risk of mechanical failure and ensuring optimal cost efficiency.

The WLC® check valves are available in a variety of ASME classes, and can be utilized in pipes of different line sizes. These valves can also be manufactured with a range of different materials for various types of applications. DFT®’s WLC® models meet stringent industrial standards, such as MSS-SP 61(for seat leakage) and MSS 126 and API 594 (for face-to-face dimensions).

Learn More

Versatile, reliable, and lightweight, the WLC® line of check valves is specifically designed to reduce the risk of water hammer and its various related issues. Allowing for low maintenance requirements and consistent service, these valves available at DFT® serve as ideal solutions for a huge range of industries and applications.

To learn more about these unique valves, download our WLC® cut sheet today.

![]()

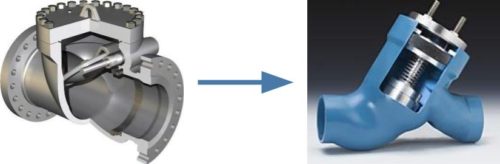

Why You Should Replace Your Swing Check Valve With a Silent Check Valve

Used to restrict fluid flow to a certain direction, check valves are employed in the vast majority of industrial processes. At DFT® Inc., we provide a wide range of check valves for use in diverse industrial applications. Our spring-assisted in-line check valves, for instance, are specifically designed to prevent water hammer by eliminating the risk of reverse flow. And, if sizing is done to account for flow rather than line size, these high-performance valves will operate reliably and efficiently for years, without the need for extensive maintenance.

In-Line Check Valves

The experts at DFT® often help clients assess their unique check valve requirements; our check valve sizing program allows us to easily determine required valve sizes before actual setup, eliminating the risk of design errors and delays. DFT® check valves can be installed in-line in any orientation; valve operation will not be hampered in any way by the specific orientation chosen, provided the flow direction is in line with the valve design (as indicated by an arrow on the valve casting).

However, for a downward flow, these check valves need to be modified slightly to support the additional weight of the disc and any static head that may be involved. While silent check valves can be employed in vertical piping or in installations requiring constant controllable pressure, swing valves should only be used in horizontal pipe runs, in which minor flow variations are expected.

When using swing check valves, users are afforded limited pressure control, as there is less control over valve opening and closing. Therefore, this type of valve is usually employed in less sensitive, large-scale pipelines carrying liquids, gases, or steam. To allow for enhanced performance, these swing check valves can be replaced by our GLC® Silent Check Valves or Excalibur® Silent Check Valves. These silent check valves have only one moving part and allow for greater flow variability than a conventional style swing check valve. Also, because the DFT Axial Flow Check Valves have so few moving components, they are more resistant to wear and tear and can maintain a longer lifespan.

However, the GLC® model is not considered a “dead-end” service valve. It is essential that the upstream, or seat end, of the valve be connected to the line until the pressure is relieved from the downstream end. The seat end of the valve must always remain bolted to the mating flange when the valve is exposed to downstream pressure in order to avoid possible blowout of the internals, as the retaining screws do not account for direct exposure to downstream pressure. In addition to eliminating water hammer, appropriately sized silent check valves can greatly improve system safety, protect critical system components like pumps, and improve overall system life while reducing maintenance costs.

Learn More

DFT® check valves are specially designed to improve the efficiency and safety of your industrial processes, and our team of experts is ready to assist in identifying the ideal model for your specific needs.

To learn more about our valve solutions, and why it may be beneficial to replace your current valves with DFT® non-slam check valves, download our new eBook, “Non-Slam Check Valves vs. Swing Check Valves.”

Steam Condensate: Important Things to Know

In our latest webinar, we provide an engaging, informative overview of steam condensate and its critical role in industry today. The webinar includes a short history of steam condensate, some of the most common problems that arise when utilizing it, solutions to those problems, and a survey of its many modern applications.

The History of Steam Condensate

The history section of our webinar discusses the origins of steam research, beginning with Thomas Savery, who invented the first steam engine in England at the end of the 17th century. He developed and patented it for use in pumping wells in 1698. Thomas Newcomen would later refine that invention in 1712, adding water tanks and pump rods so that deeper water mines could be accessed with steam power. In 1778, James Watt further built on these discoveries, employing a gearing system that allowed a steam engine to drive a flywheel in order to produce rotational power, spurring the development of the steam locomotive. These inventions, all originating in England, would become the catalyst for the Industrial Revolution and shape the world as we know it today, with steam power playing an instrumental role in a wide range of industries — including mining, chemical processing, petroleum production, textiles, pulp and paper production, and, most importantly, power generation.

The Basics of Steam Condensate

The webinar then describes the basics of steam condensate, answering the question: Why steam? The main advantages of steam stem from its high efficiency and ease of transportation and control, which make it an ideal medium for heat transfer. Steam power is easy to create due to the abundance of water and wide range of heating options available; simply by managing the temperature and pressure of steam, it can be used for much of the work that powers the industrial world. The three biggest users of stream power today are the power generation, pulp and paper manufacturing, and chemical processing industries; in these sectors, steam is used for all manner of jobs, including automation, dilution, fractionation, quenching, mechanical drive, and stripping.

Common Issues With Steam Condensate

There are some challenges involved in using steam condensate, however. For instance, it’s important to maintain high-quality steam in order to prevent a variety of pipe and valve issues, as low-quality steam can reduce heat-transfer efficiency by as much as 65%. Also, if CO2 combines with steam condensate, the formation of carbonic acid and CO2 gas may occur, which can cause rapid corrosion. Luckily, this can be managed through the use of steam traps, which keep water separated from the steam. Engineers and plant managers must also consider the line sizing of pipes in order to prevent condensate collection, as well as the location and configuration of equipment, the insulation methods used, and the types and quality of different valves used for different applications.

Steam Condensate Q&A

Below, we’ll delve into some of the most common questions we receive regarding steam condensate.

- Q: Do you propose using traps for all piping loops with low points in offsite piping?

- A: Yes. The condensate must be removed from the lines in order to prevent water hammer or corrosion of the piping itself.

- Q: Can you share some guidelines for specifying cracking pressure? Is there a tool one can use?

- A: It’s best to work with directly a manufacturer to pinpoint the best low cracking pressure options for your specific application. In-line (silent) check valves typically have a cracking pressure of approximately 0.5 psi. Depending on the condensate return piping layout, a standard cracking pressure (CP) valve may allow excess condensate to accumulate. In these scenarios, a lower CP is ideal; options will vary from manufacturer to manufacturer. At DFT, we offer solutions that allow for a CP as low as 0.1 psi.

- Q: Are there any formulas or tables available for steam pipe sizing?

- A: We recommend the reference handbook, “Crane Technical Paper No. 410.”

- Q: Are low cracking pressure check valves only necessary in certain types of steam systems?

- A: Low cracking pressure valves should be used for condensate return lines, not main steam lines. Also, low CP valves will help reduce the accumulated condensate in return lines.

Learn More

All of these matters and more are discussed in our comprehensive online webinar and its accompanying slides. To learn more about steam condensate, view DFT’s prerecorded webinar today.