DFT Model PDC® Solves Air Compressor Problems

Inside their control valve test and research facility, a major valve manufacturer was using two reciprocating air compressors that were designed to run until the stored air pressure in the extremely large volume tanks reached a set point.

They would then shut off for anywhere from several minutes to several hours, depending on demand. During the shut-off intervals, the wafer-style swing check valves on the discharge side were leaking, tripping the relief valves and threatening to over pressurize system components.

The Use of DFT Technology

On several occasions, the continual pounding of the valve seats resulted in total failure, which caused the system to blow the intermediate stage safety relief valve and totally shut down.

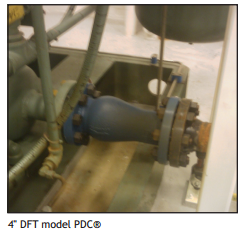

Despite being a valve manufacturer themselves, they recognized that our insight into check valve technology would help them find the best way to address shut-off performance and longevity. Our solution was to replace the valves in both the 200 hp/1000 psig and 400 hp/400 psig air compressors with DFT model PDC® check valves.

Preventing System Pressure from Bleeding Back

Designed specifically for reciprocating equipment, these silent, non-slam check valves prevented system pressures from bleeding back into the compressor when the machines were off as well eliminated the unacceptable reverse flow leakage. The machines now run in optimal states and are no longer susceptible to shut down.

If you are interested in learning more about this project, or if you have a situation that would benefit from our insight into valve technologies, contact us today.

Comments are closed