1911

Originally named Durabla Manufacturing Company was founded in New York City in 1911

1919

Durabla Manufacturing Company starting manufacturing valves for reciprocating pump applications. Durabla Manufacturing Company developed a method of strengthening the metal disc with corrugations.

Valves became a part of the product line in 1919 with the development of pump valves used in reciprocating pump applications. The development of the technology of the disc design was crucial to higher strength requirements being demanded by the US Navy. US Navy used DFT valves on Boiler Feed Water and Bilge pumps.

1940

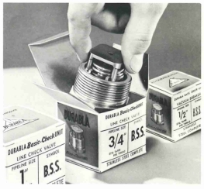

Check Valves for cryogenic needs for the famed Manhattan Project are a key part of the history of DFT. The valves used in reciprocating pumps led to the valve that you will recognize as the Basic Check valve still being sold today.

The US government & Kellox asked DFT to develop: Non return Check valve for -320° F service (Liquid N2), for the Manhattan Project. This check valve was named the Basic-Check®

1943

The development of Basic-Check®, ultimately led to the development of the Vacuum Breaker

1969

Company moved from New York City to Strafford, PA.

1977

Development of GLC®

The GLC is available in 1” to 30”, ANSI 150 to 2500, Short pattern face to face. Body materials include the standard; WCB, 316SS, other alloy body materials are also available. 316SS trim is standard, flanges are raised face style.

1979

Company moved to Paoli, Pa

1980

Development of WLC®

The WLC was developed next. This valve is a wafer style body and is available in 1” to 10”, ANSI 150 to 2500, Wafer style, WCB, 316SS and other body materials. 316SS trim is standard.

1985

DFT located to its present location in Exton, PA

1986

Development of PDC®

The PDC® is a pulse dampening check valve developed especially for the discharge of reciprocating air or gas compressors. 2” to 12”, ANSI 150 to 1500, ANSI B16.10 face to face dimensions, WCB & 316SS body materials, 316SS trim is standard, Flanged ends.

1987

Development of Excalibur®

The Excalibur is available from 2” to 24”, ANSI 150 to 1500, ANSI B16.10 face to face dimensions, WCB, 316SS and other body materials, 316SS trim is standard, Flanged or Butt weld ends.

1989

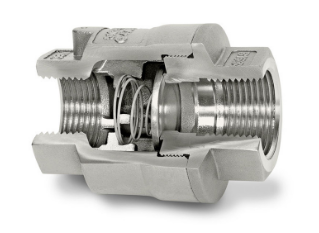

Development of SCV®

The SCV was introduced in 1989 and available in sizes from 1/2” to 3”, threaded & socket weld ends. The standard materials of construction are 316 SS body and trim, 750 & 3600CWP. Not long after, the SCV-R® was developed due to the need for higher cracking pressures.

1996

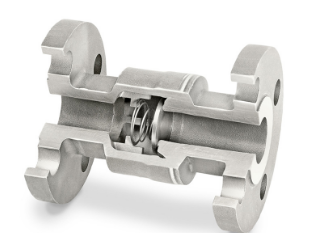

Development of DLC®

The DLC® in-line check valve is available from 1/2” to 3” in ANSI 150 & 300 with flanged ends. It has a 316SS body and trim. The electron beam welded body joint allows this valve to handle temperatures to 700°F with assurance of a leak tight body joint.

1998

Development of DSV®

The Sanitary check valve, our DSV®, is built to 3-A standards, has clamped ends, available in vertical and horizontal line configurations in ½” to 3” line sizes.

1999

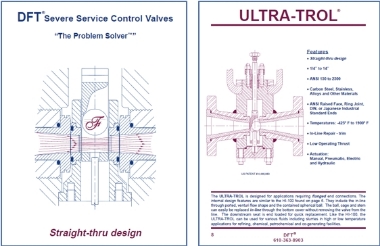

DFT acquired a Severe Service Line of Control Valves HI-100: This control valve has a straight-thru Venturi flow design to minimize cavitation. UltraTrol: This has the same internal design features of the Hi-100, but this style was designed for flanged, lined pipe applications.

2007

Development of ALC® The ALC conforms to API 594 face to face requirements and will be an exact length replacement for double door check valves.

2008

Development of FBC®

The FBC is designed for the absolute minimum face to face requirements. This valve fits between 1” thru 4” Schedule 40 steel pipe flanges.

2013

Development of the TLW®:

The TLW is a tapped lug wafer style check valve engineered for applications where exposed bolts are not suitable.