Category Archive: Uncategorized

DFT Achieves Safety Excellence: 365 Days and Still Counting!

Article written by JP Hanson, a Research Specialist from the Walter Cronkite School of Journalism.

When it comes to manufacturing, safety is critical to DFT’s employees, and the company as a whole. DFT has a Safety Program in place that is overseen by company Vice President Arie Bregman and has an eight-person safety committee headed by Dennis Petrucci and Vinnie Corsi.

In 2020, DFT achieved a record of 365 days without an OSHA recordable accident. Without the frontline leadership of Dennis Petrucci and Vinnie Corsi, the goal would have been a mere target in the distance. Petrucci and Corsi have professional and academic backgrounds in safety practices, specializing in the manufacturing industry. Their knowledge and experience aided in reimagining DFT’s safety focus and implementing the programs that accomplished this achievement.

With immense pride in his team, General Manager Arie Bregman states, “While we can reassure and educate in the workplace, we trust that our people take home what we teach and ultimately engrain these aspects into everyday habits.”

Whether on the production floor or at home, integrating safety into the whole team’s daily routine is essential. For example, DFT invests in fire extinguisher training for its employees, which benefits their awareness on and off the clock. “Each person that walks through the door is reminded of their family, and how happy they would be to see them pull in the driveway for dinner” said Arie Bregman.

Building on this progressive approach to accident prevention, safety leaders are directly encouraged to leverage non-workplace exposures in their training sessions, thereby better cultivating an atmosphere of hazard avoidance. For example, Mr. Bregman enjoys working on automobiles and ties his safety tricks and tips within their meeting content to allow some room for risk management parallels outside of work. These parallels remind employees that their supervisors are practicing what they preach, both inside and outside the walls of DFT.

DFT has a lot to be proud of: Their customers are exceptional. Their products and services are world-renowned. Their team is cohesive, focused, and committed. And their latest safety accomplishment of 365 days without an OSHA recordable accident is an ideal result, and something for their competition to aspire to.

As of the date of this article, the DFT Safety Scoreboard is still adding days to the full year of safety excellence.

Q&A: Superior Protection for Pumps and Compressors – Why Axial Flow Check Valves Are Your Best Choice

Axial Flow Check Valves are used in a wide range of pumps and compressors in a vast array of industries. DFT® hosted a webinar on this subject which outlines the differences between check valves used in their applications, as well as the advantages or disadvantages that each one presents.

Here at DFT®, we frequently field questions regarding this topic. So we are sharing a few common questions that came in from the webinar and were answered by host Arie Bregman.

Q: What are the typical installed cost differentials between swing check valves and axial check valves?

A: Swing check valves are usually less expensive when you initially buy them, but the lifetime cost to own an Axial Flow design valve that is properly sized for the application will always cost you a lot less money over the lifetime of the valve. Swing check valves cannot be sized for low flow applications, so they will wear out and fail causing additional maintenance costs and system shutdowns. The cost to take a prematurely failed valve out and either service or replace it far exceeds the cost differential to get the right valve up front.

Q: What type of check would you use in gas service with intermittent liquids? After compressor?

A: DFT®’s model GLC® or Excalibur® would be best suited for this kind of intermittent gas/liquid service.

Q: Can Axial Flow check valves be used in very viscous flow?

A: Yes, however depending on the viscosity and the min/normal/max flow conditions, other internal modifications may have to be considered like higher cracking pressure springs.

Q: How would you compare CV of a swing, dual plate, and Axial Flow check valves?

A: The differences in head loss between Axial Flow and Swing checks is a function of the Cv of the specific valves you are looking at – head loss must be calculated on a case by case basis. There will usually be a slightly higher head loss for the Axial Flow versus a Swing check, but in many cases, this is not consequential. In cases where pressure loss is a very important piping design consideration, the Axial Flow check valve can be engineered with lower cracking pressure springs and low friction coatings to reduce the amount of energy required to open the valve.

Q: Do you offer a sizing calculator for check valve selection?

A: DFT® does offer sizing services through our Regional Sales Managers or our Inside Sales team. We will be rolling out a new version of our sizing and configurator program very shortly to our Tier 1 distributors. For more information please use the following link to contact someone in your area: https://www.dft-valves.com/check-valves-territory-map/

To learn more on why Axial Flow check valves are your best choice when it comes to pump and compressor protection, you can reference our webinar or contact us today!

Other relevant resources include:

Axial Flow Check Valves: The Best Choice for Pumps & Compressors

Pumps and compressors are used in a wide range of industries such as pharmaceutical, food & beverage, petrochemical, natural gas, power generation, chemical industries, and building maintenance. Pumps and compressors transport fluids and compressible gases, respectively, from one location to another.

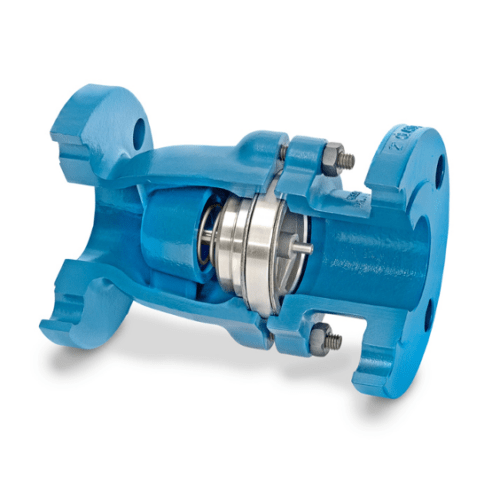

Axial flow check valves are an important protection for pumps and compressors as they induce flow in one direction and prevent backflow in the opposite direction. Backward flow can result in extensive damage to equipment, and axial flow check valves are crucial to protecting your investment.

If you missed our webinar, Superior Protection for Pumps and Compressors – Why Axial Flow Check Valves Are Your Best Choice, check it out today for more information about how axial flow check valves are the best choice:

Common Problems & Solutions of Pump and Compressor Check Valves

There are some frequent problems pump and compressor valves face: double door, swing check, and tilting disc check valves often fail, water hammer and pressure pulsation can cause damage to valves and other system parts, and the limited spatial requirements faced by pumps can often lead to less room for traditional check valves. These problems can be solved by installing DFT® axial flow check valves to protect your pumps and compressors.

Double Door Check Valve Failure

Double door check valves are commonly used in air compressors. However, these valves can fail due to poor design, particularly during varying flow conditions. As a solution, DFT® axial flow check valves can be used in place of double door check valves. The design of the axial flow check valve allows pulse-dampening chambers to keep the discs of the valve open during flow reductions.

Pressure Pulsations

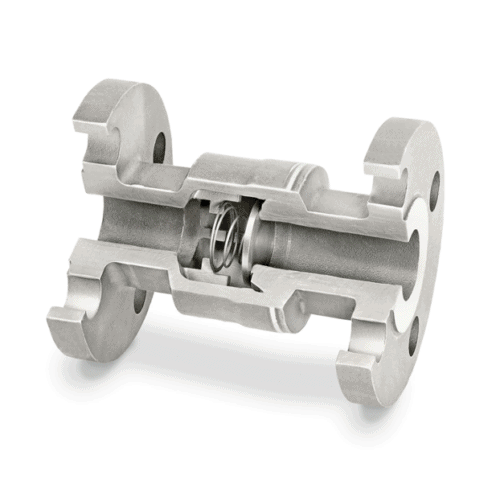

Pressure pulsations are caused by the intermittent reduction in pressure due to the reciprocating motion of a reciprocating compressor. The pressure fluctuation causes pulsation shock waves in the system, which increases wear on system components. However, axial check valves consist of no swinging parts and therefore reduce wear on system components, contributing to a longer lifetime in comparison to other valve types. The DFT® model PDC® axial flow check valve was designed for the discharge side of a reciprocating compressor in air and gas applications.

Water Hammer

Water hammer is the phenomenon that occurs when a liquid comes to a sudden stop and generates shock waves inside the pipe. The resulting high pressure can cause significant damage to pipe lines, gaskets, gauges, pipe hangars, and other components. Swing check valves, tilting disc check valves, and double door check valves contribute significantly to water hammer. Replacing these valves with an axial flow, spring-assisted, silent check valve, such as DFT® ALC® axial flow check valve, can reduce the effects of water hammer.

Spatial Requirements

A common problem faced when using a pump, is limited space for valves and pipes. Pumps are extremely loud when in operation and therefore are usually put in special rooms. This leaves less room for valves and piping. Axial flow valves can handle turbulence better than conventional check valves. This makes them an excellent option when space is limited. Additionally, axial flow check valves can be installed on both vertical and horizontal pipes.

Advantages of Using Axial Flow Check Valves

Axial flow check valves offer several advantages over other types of check valves, such as:

- Rapid closing action (prevents water hammering)

- The ability to be properly sized for each application

- Durability

- Increased valve longevity

- The ability to accommodate low-pressure drops and high flow

- Non-slamming opening and closing action

- Tight shut-off leading to zero leakage

- Various end-to-end options

- The ability to be installed in both horizontal and vertical orientation

Axial flow check valves offer many advantages over other types of check valves. DFT® axial flow check valves can save down time and money by preventing damage and increasing the lifetime of your pumps, valves, pipes, and other system parts. Check out our online technical catalog for more specific information about our axial flow check valves. To discuss your needs with a valve expert at DFT® contact us, or request a quote today!

You may also find interest in the online technical catalog and our webinar Q&A.

Features of the DFT® HI-100® Severe Service Valve

Severe service valves are used in applications involving periodic or extended exposure to extreme temperatures, high pressures, and/or abrasive, corrosive, or erosive compounds. Due to the harsh operating conditions to which they subjected, these valves often feature specialized construction materials and body designs to ensure they maintain their integrity during use.

At DFT®, we’ve manufactured world-class valves for over 75 years. The following article and video provides an overview of the HI-100® severe service control valve, its key features, benefits, and industrial uses.

Features of the HI-100® Control Valve

HI-100® control valves are available in 1-inch to 12-inch sizes with butt weld, socket weld, and flanged configurations. All variations feature an in-line, straight-through venturi design based on Bernoulli’s principle. This unique design allows them to resist cavitation and flashing and accommodate greater fluid flow than similarly sized globe control valves. As these valves are position seated, they rely on the pressure in the flow stream to generate the force necessary to achieve Class 5 shut-off with metal to metal seating. An additional benefit of position seating is that it results allows for the use of smaller actuators.

Benefits of the HI-100® Control Valve

HI-100® control valve durability and longevity help industry professionals reduce valve maintenance costs in their facility. Additionally, their design facilitates quick and economical in-line change trim replacement, which further lowers the cost of ownership when compared to competitors’ products.

For fluid handling applications involving erosive compounds, our Ultra-Trol® valves are the ideal solution. These valves feature hardened metal sleeves at the inlet and outlet that prevent erosive materials from damaging the valve body. For fluid handling applications involving moderate pressure drops without service interruption, our MSV-100® valves are more appropriate.

You May Also Like: Control Valves for Severe Service Applications

Industry Uses of the HI-100® Control Valve

At DFT®, we’ve manufactured world-class severe service control valves for over 75 years. Throughout our years in business, these valves have found application in a wide range of industries, including the following:

- Chemical

- Petrochemical

- Power

- Pulp and paper

- Refining

The HI-100® Control Valve From DFT®

For customers that need severe service control valves, DFT® is here to assist you.

At DFT®, we offer a broad selection of check and control valves, including severe service control valves. Whether a customer requires a valve for a critical or non-critical application, we can meet their requirements. For more information about our product offerings, check out our catalog or contact us today. To receive pricing details, request a quote.

Common Causes of Swing Check Valve Failure and How to Diagnose and Resolve Them

Swing check valves use a hinged swinging disc to block and control the movement of fluid in a system. As they are used to prevent the reverse flow of fluids or gases, any failure can lead to leakage, loss of pressure, contamination, overflow, and, in the most severe cases, complete system failure. Below we discuss some of the most common causes of swing check valve failure, how to diagnose them, and appropriate solutions.

Why Do Swing Check Valves Break?

Swing check valves require reverse flow to close. This design causes them to malfunction or fail when subjected to insufficient or improper operating conditions. Understanding the cause of damage helps determine the best solution. Some of the most common causes of failure in swing check valves include:

Low Flow Application

In low flow applications, swing check valves are not able to maintain consistent flow when the system does not provide sufficient pressure. The insufficiency of pressure causes the disc to open and close frequently, causing excessive wear on the hinge pin and pivot arm where the disc may break off entirely. This can cause significant damage to downstream equipment.

Water Hammer

Water hammer refers to a pressure increase due to the sudden stop or change in the direction of the fluid traveling through the valve. It is a common occurrence with swing check valves, which rely on the reversal of fluid flow to close quickly. Over time, the repeated closing of the disc against the valve body may cause the disc to detach from the swing arm. Additionally, water hammer can cause other serious system issues, such as ruptured pipes and damaged fittings.

Improper Selection or Installation

When using a swing check valve in a fluid system, both proper selection and installation are key to safe and reliable system performance. The valve chosen should suit the system’s piping, material, orientation, flow direction, and flow rate to avoid inefficient performance and premature component wear. Additionally, when installing the valve, industry professionals should keep in mind positioning and orientation; the valve should not interfere or be influenced by other system components and should be oriented correctly in relation to flow. Swing check valves will not work in a vertical flow down application.

For additional information about how selection and installation affect valve and fluid system performance, watch DFT®’s webinar on Check Valve Installation and Piping Design Guidelines.

How to Diagnose Failing Swing Check Valves

The signs of a failing swing check valve are often audible. When the disc opens and closes repeatedly (because of low-pressure flow) or violently (because of water hammer), it emits a tapping or hammering sound, respectively. While the swing check valve may not be broken at this point, these noises mean that the disc, swing arm, and hinge pin are experiencing significant stress, which, over time, leads to wear and failure.

Swing check valves will also start to stick as they begin to break down. Sticking occurs when the valve is constantly tapping the top of the valve body and peening over the casting material. This repetitive action can grab the disc and prevent it from closing. These operating conditions can cause leakage or damage to other system components.

Replacing Failing Swing Check Valves

At DFT®, our team of valve experts will provide facts on how DFT®’s axial flow check valves provide safety and performance. Drawing from our extensive knowledge of valve selection and sizing, we determine which valve is right for your needs. For custom sizing, fill out and submit our datasheet.

For fluid systems that employ the use of swing check valves, we offer superior quality alternatives, such as our Excalibur® Silent Check Valve and DLC® Check Valve which ultimately prevent water hammer and can meet the demands of a low flow application, unlike other traditional swing check valves.

To learn more about our axial flow check valves that are replacements for swing check valves or our wide selection of non-slam check valves contact us or request a quote today.